As the global textile industry moves toward greener, more responsible practices, the production of polyester full stretch yarn is also undergoing a quiet but impactful transformation. Once seen purely as a synthetic material optimized for durability and performance, polyester is now being reevaluated through the lens of sustainability. Advances in both raw material sourcing and process engineering are enabling manufacturers to offer eco-friendlier solutions without compromising on yarn quality—a development that’s increasingly important to brand owners, OEMs, and supply chain partners alike.

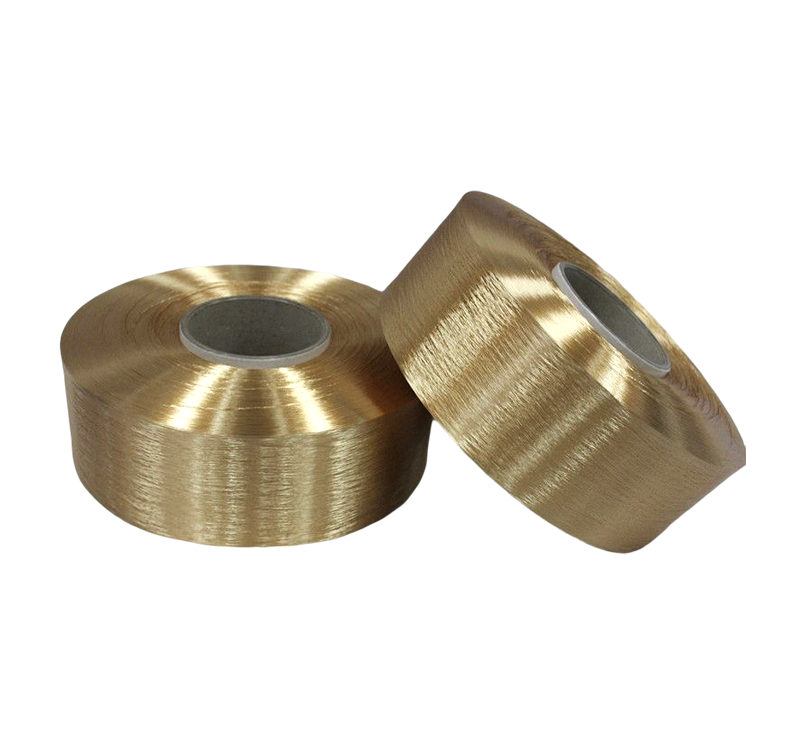

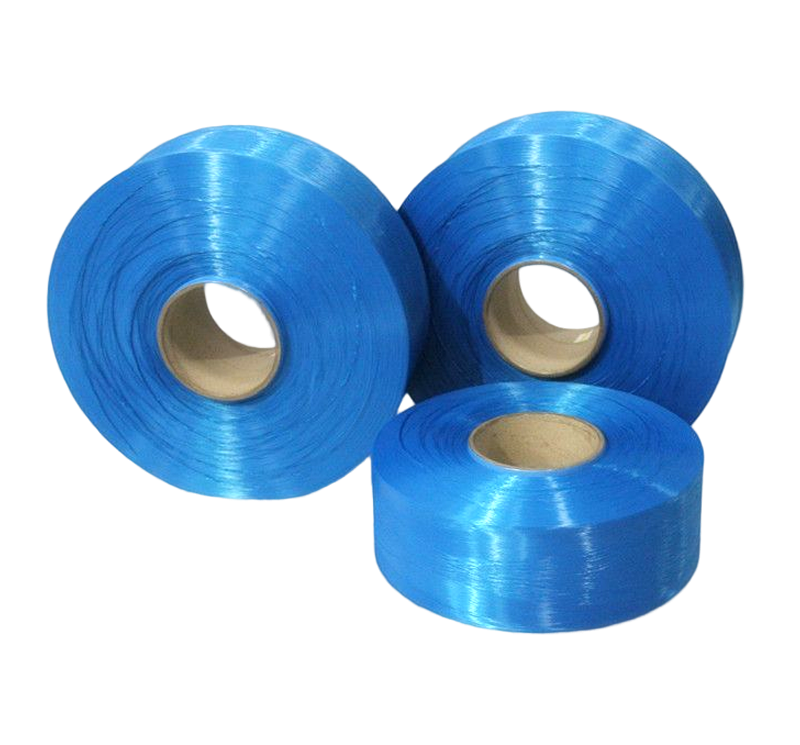

One of the most notable shifts in recent years has been the incorporation of recycled PET (rPET) chips into the spinning process. These chips, derived from post-consumer plastic bottles or post-industrial waste, serve as a raw material substitute for virgin polyester without altering the mechanical properties of the resulting polyester full stretch yarn. When sourced and processed properly, recycled chips offer the same strength, elongation, and dye uptake as traditional chips, while significantly reducing the carbon footprint of the final product. Our team has invested in testing and validation systems to ensure that our eco-series yarns meet the same performance benchmarks as our conventional lines.

Energy consumption during spinning is another focus of environmental optimization. Traditional yarn production relies heavily on thermal energy, but newer native spinning technologies—like the one we use—optimize heat transfer, reduce waste, and require less energy input per kilogram of yarn. These improvements not only cut operational emissions but also lower production costs over time, delivering a dual benefit for environmentally conscious customers who still need competitive pricing. For polyester full stretch yarn, which is often produced in high volumes, even marginal gains in energy efficiency can result in substantial environmental savings across the supply chain.

Beyond raw materials and energy, water usage and emissions control during production are also being scrutinized. By implementing closed-loop water systems and investing in efficient filtration technologies, we’ve significantly reduced wastewater discharge and maintained compliance with stricter environmental standards. This ensures that the production of our stretch yarn products supports not only economic value but ecological responsibility—a key concern for international buyers facing growing pressure to meet sustainability targets.

Moreover, sustainability isn’t just about reducing harm; it’s also about improving longevity. Polyester full stretch yarn is inherently durable, and its long service life reduces the need for frequent replacements in end-use products like sportswear, home textiles, and industrial webbing. By offering yarns that last longer and perform consistently, we contribute to reduced overall consumption—another overlooked dimension of eco-conscious manufacturing. When customers choose products that don’t require frequent repair or disposal, the environmental savings multiply over time.

It’s worth noting that traceability is becoming a growing concern, particularly for export-oriented brands. That’s why we provide documentation on material origins, production conditions, and sustainability certifications for our yarns upon request. These records help our clients meet international environmental labeling standards and provide transparency to downstream consumers. The demand for traceable, responsible polyester full stretch yarn is no longer a niche—it’s fast becoming the industry norm.

As a forward-thinking manufacturer committed to responsible growth, we’re proud to offer a range of polyester full stretch yarn products that reflect both technical excellence and environmental care. Whether you’re sourcing for high-volume apparel or specialized textile applications, you’ll find that sustainability and performance no longer have to be a trade-off—they now go hand in hand.

English

English 中文简体

中文简体

Home

Home