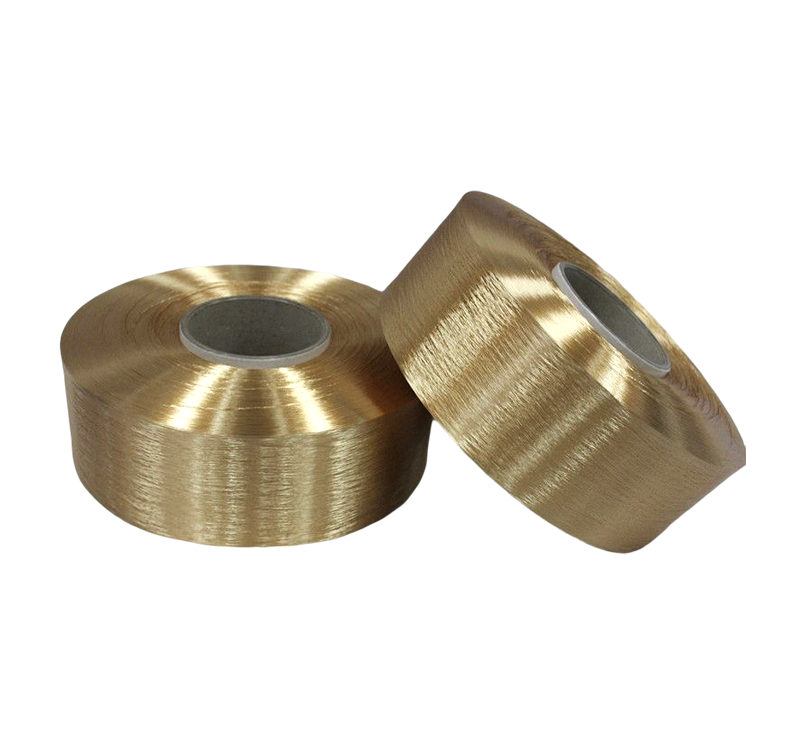

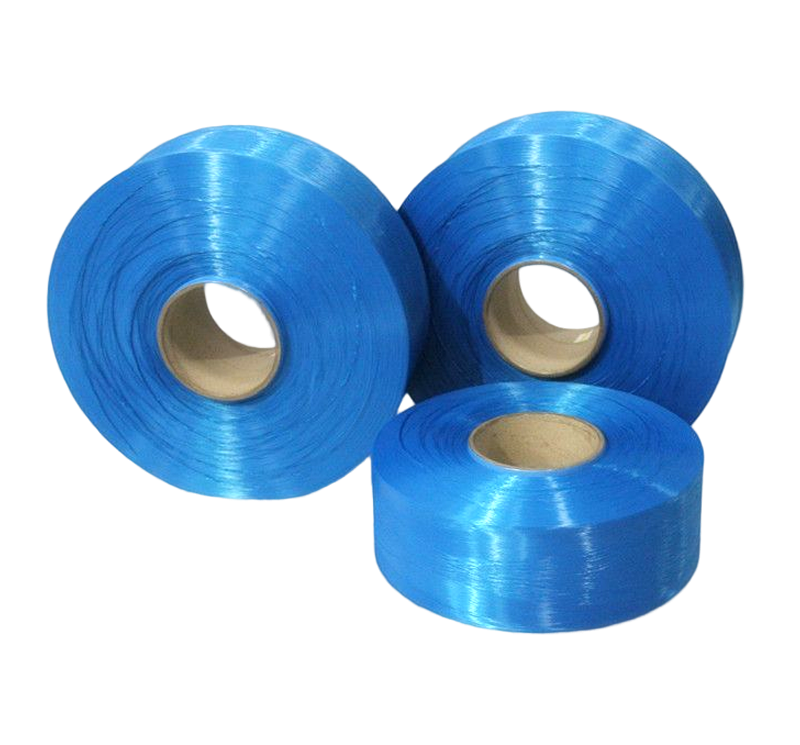

When working with polyester full stretch yarn, achieving consistent fabric quality in round knitting and warp knitting processes requires careful attention to several key factors. As a trusted manufacturer, we understand that this type of yarn’s unique elasticity and strength bring both opportunities and challenges during textile production. Optimizing machine settings and handling techniques ensures you unlock the full potential of full stretch yarns in your home textile or luggage fabric lines.

One critical aspect is tension control. Polyester full stretch yarn responds differently to tension compared to regular polyester yarns because of its enhanced elasticity. Excessive tension can overstretch the yarn, leading to uneven fabric texture and compromised recovery properties, while too little tension may result in loose loops or fabric distortion. Experienced operators should calibrate tension precisely to maintain uniform stitch formation and ensure the final fabric maintains its shape and stretchability.

Machine speed is another important factor in processing polyester full stretch yarn. Running knitting machines too fast can cause yarn breakage or inconsistent loop formation, particularly on warp knitting machines where yarn feed paths are complex. We recommend gradual speed adjustments paired with close monitoring of fabric appearance and machine feedback to find the optimal balance between production efficiency and fabric integrity.

The unique behavior of full stretch polyester yarn during knitting also requires attention to yarn feeding systems. Proper feed tension and alignment prevent twisting or slippage, which can lead to defects such as dropped stitches or uneven gauge. Our extensive experience shows that integrating advanced feeding mechanisms tailored for stretch yarns significantly reduces downtime and enhances overall fabric quality.

Moreover, heat settings during any finishing stages must be carefully optimized. Polyester full stretch yarn maintains its properties best when heat exposure is controlled, preventing distortion or loss of elasticity. This is especially relevant for home textile fabrics and luggage materials that demand both durability and a refined aesthetic.

For manufacturers seeking consistent, high-quality fabric production, partnering with a reliable supplier of polyester full stretch yarn—backed by technical support—makes all the difference. Our product’s stable color fastness and stretch performance combined with expert guidance help you overcome common production challenges, ensuring your final textiles meet the highest standards.

Ultimately, mastering these process optimizations delivers fabrics that are not only visually appealing but also resilient and comfortable, meeting end-user expectations in diverse applications. By sharing our insights on round and warp knitting best practices, we aim to support your production success and reinforce why our polyester full stretch yarn is the ideal choice for demanding textile projects.

If you’re ready to elevate your fabric manufacturing with premium polyester full stretch yarn and expert advice, we’re here to assist you every step of the way.

English

English 中文简体

中文简体

Home

Home