Polymer Selection:

The journey of manufacturing polyester low elastic yarn begins with a crucial step—the selection of the polymer. Unlike regular polyester yarn, which typically uses a standard polymer composition, low elastic yarn requires a specialized polymer with a modified molecular structure. This modification is essential to achieve the desired level of elasticity in the final yarn product.

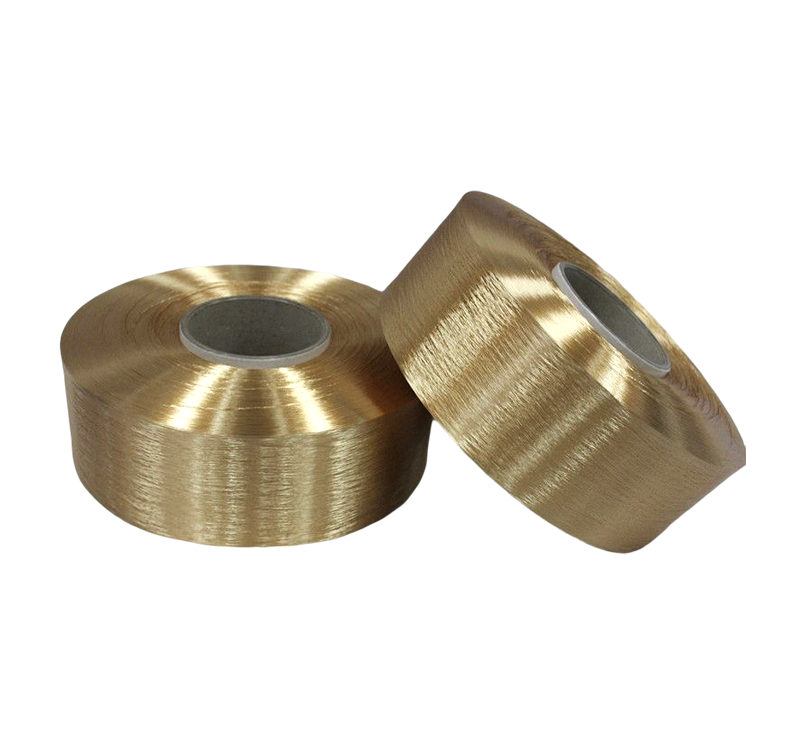

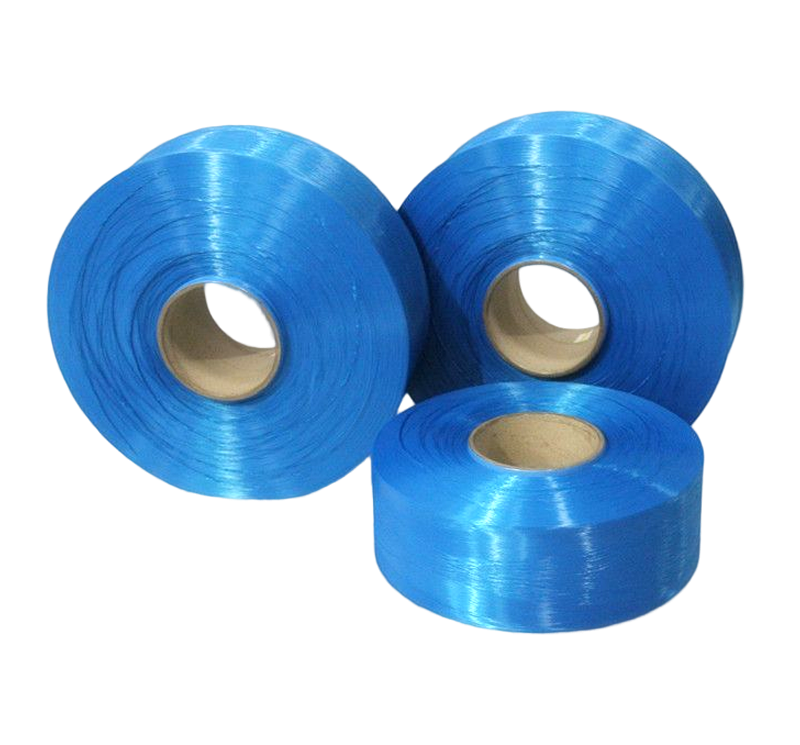

Spinning Process:

Once the suitable polymer is chosen, it undergoes the spinning process. During spinning, the polymer is melted and extruded through spinnerets to form continuous filaments. Here, the manufacturing process for low elastic yarn diverges from that of regular polyester yarn. Modifications are made to the spinning conditions, such as adjusting temperature, pressure, or incorporating specific additives or modifiers. These adjustments play a crucial role in controlling the yarn's elasticity, ensuring it remains lower than that of regular polyester yarn.

Drawing and Orientation:

Following extrusion, the filaments undergo drawing and orientation processes. These processes align the polymer molecules and enhance the yarn's strength. In the case of low elastic yarn, the drawing process is adjusted to achieve a lower degree of molecular orientation. This intentional modification contributes to reducing the yarn's elasticity while maintaining its structural integrity and other desirable properties of polyester.

Heat setting is a vital step in the manufacturing process of polyester yarn, including low elastic yarn. It involves subjecting the yarn to controlled heat to stabilize its structure and dimensions. For polyester low elastic yarn, the heat setting process is fine-tuned to preserve a controlled level of residual elasticity in the yarn. This residual elasticity ensures that the yarn retains some stretch while remaining less elastic than its regular polyester counterpart.

Finishing Treatments:

To further enhance its performance and properties, low elastic yarn may undergo additional finishing treatments. These treatments could include lubrication or surface treatments to improve the yarn's handling characteristics, appearance, and suitability for specific applications. Each finishing treatment is carefully tailored to complement the unique characteristics of polyester low elastic yarn.

English

English 中文简体

中文简体

Home

Home