In the manufacturing of polyester full stretch yarn, one of the most critical—yet often underestimated—factors influencing end-product quality is the selection and handling of polyester chips. These chips form the foundation of the yarn's structural integrity and functional performance. Any inconsistency in their quality, moisture content, or molecular weight can directly translate into variability in yarn properties such as tensile strength, dye uniformity, and elongation at break. For businesses aiming to maintain a consistent fabric output, understanding the upstream influence of chip quality is not just technical know-how—it's a practical necessity.

High-grade polyester chips typically exhibit superior intrinsic viscosity and uniform crystallinity, which are key to achieving optimal melt flow during the spinning of polyester full stretch yarn. When these chips are evenly polymerized and thoroughly dried, the native spinning process can run smoothly, resulting in fewer yarn breaks, better filament cohesion, and higher production efficiency. On the other hand, low-purity or poorly processed chips often lead to fluctuating viscosity in the spinning stage, producing inconsistent filament diameters that may compromise downstream knitting or weaving processes.

Moisture control in polyester chips is particularly crucial. Even a minor deviation in residual moisture can hydrolyze polymer chains during extrusion, weakening the molecular bonds and leading to lower tenacity in the final yarn. That's why our in-house quality control systems incorporate strict pre-drying protocols and continuous monitoring, ensuring that the polyester full stretch yarn we produce consistently meets the durability requirements of high-performance applications, from webbing and luggage to home textile fabrics.

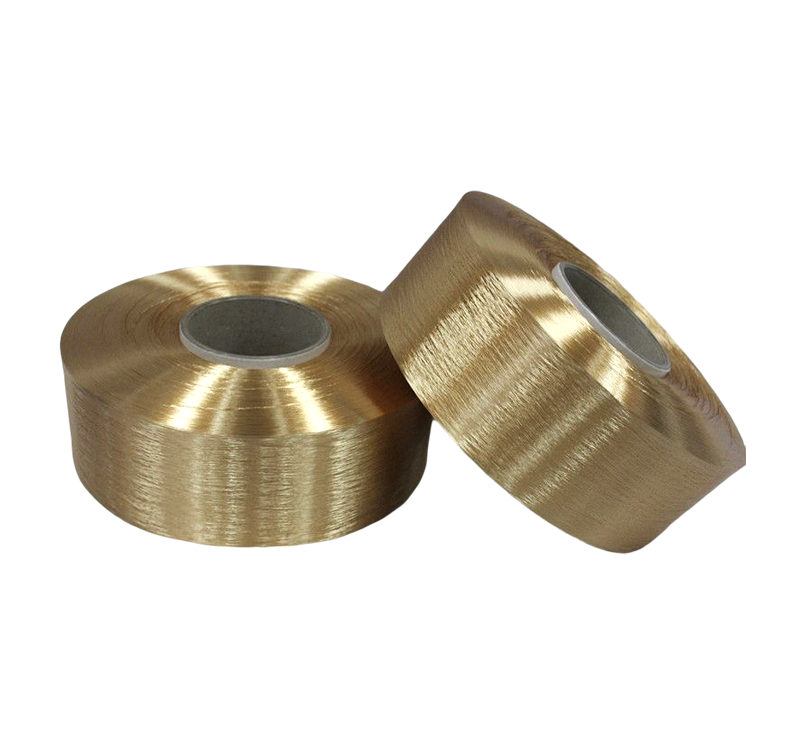

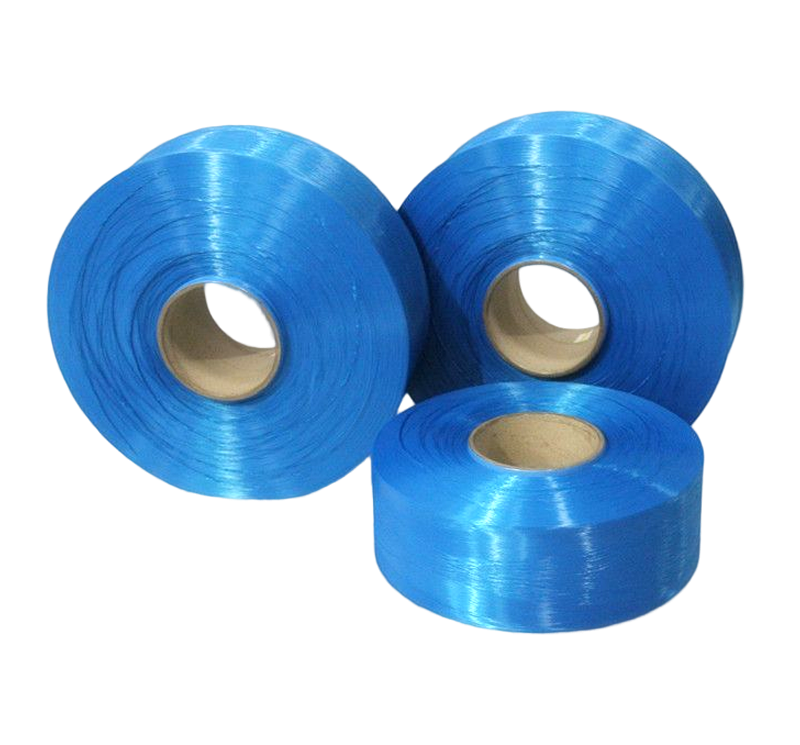

Color masterbatch integration is another area where chip quality plays a pivotal role. Uniform dispersion of pigments during the melt phase is only possible when the chips themselves maintain a consistent melt flow rate and thermal stability. Irregular chip batches can cause streaking or uneven coloration in the yarn, which becomes even more visible in end-use products. For manufacturers producing yarns in high-visibility or brand-specific colorways, the reliability of chip quality directly affects product acceptance and market competitiveness.

From a sourcing perspective, we’ve learned that establishing long-term relationships with dependable chip suppliers—and regularly auditing their facilities—has a measurable impact on our final output. Batch-to-batch consistency not only reduces waste but also minimizes machine downtime, which can be a hidden cost for many yarn producers. This operational stability is one reason why customers worldwide trust our polyester full stretch yarn for critical applications, where fabric quality cannot be left to chance.

In today’s increasingly demanding textile market, the expectation is not just for a yarn that performs well, but for one that performs consistently—day in and day out. That kind of reliability begins far before the spinning floor; it starts with polymer science, with materials engineering, and with a disciplined approach to chip sourcing. As a professional manufacturer with deep roots in the industry, we understand that small details upstream make all the difference downstream.

If you’re a fabric producer, OEM partner, or sourcing agent looking for a dependable supply of polyester full stretch yarn, consider working with a partner who doesn’t cut corners at the molecular level. Our products are engineered for excellence, starting with every chip.

English

English 中文简体

中文简体

Home

Home