The global demand for polyester full stretch yarn is continuously evolving, with manufacturers and exporters facing both opportunities and challenges in this competitive market. As a key material used in a wide range of products, from home textiles to luggage, the market for FDY (polyester full stretch yarn) has seen significant growth. In recent years, the versatility and performance of this yarn have made it a preferred choice for manufacturers worldwide, and as demand rises, so do the complexities of managing supply chains and responding to market needs.

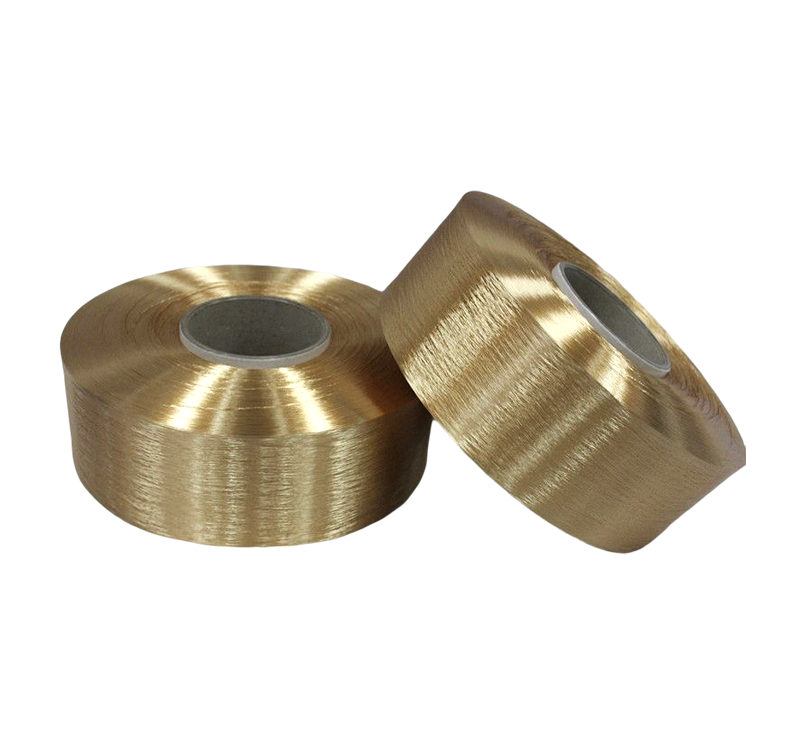

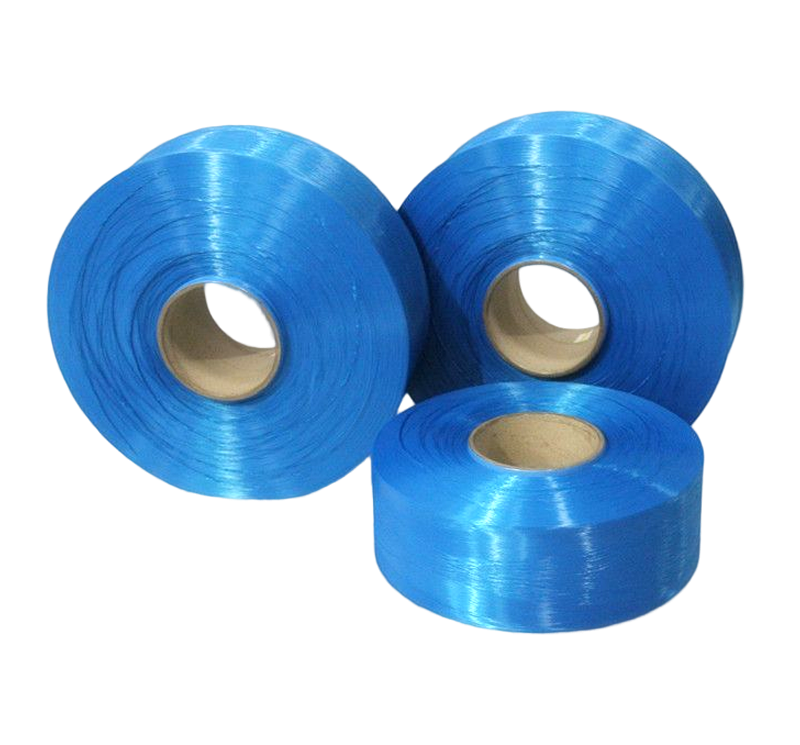

One of the major factors driving the growth of the polyester FDY yarn market is its widespread use in applications that require durability and elasticity. The expanding use of polyester full stretch yarn in home textiles, such as upholstery, curtains, and carpets, has contributed to a robust demand. Additionally, its use in clothing, webbing, and even athletic gear has positioned it as a valuable component in numerous sectors. As consumer preferences shift toward high-performance, long-lasting materials, polyester FDY yarn continues to offer the flexibility that meets these demands.

However, the market is not without its challenges. Manufacturers and exporters are dealing with fluctuating raw material prices, which can have a direct impact on the cost and availability of polyester full stretch yarn. The price of polyester chips, the primary input material, has been unpredictable due to changes in global supply chains, such as fluctuations in oil prices and transportation costs. This volatility requires manufacturers to adopt agile strategies to maintain competitive pricing while ensuring consistent quality for their customers.

Another challenge facing the polyester yarn market is the increasing emphasis on sustainability. With the global shift toward eco-friendly practices, consumers and companies alike are seeking more sustainable options for their textiles and fabrics. Manufacturers of polyester full stretch yarn are increasingly expected to adopt eco-conscious production methods. Recycling and the use of sustainable resources in yarn production are becoming crucial factors for those looking to stay competitive. As environmental concerns continue to rise, businesses that fail to adapt to sustainability trends risk falling behind in the marketplace.

As a manufacturer of high-quality polyester FDY yarn, staying ahead of market trends is essential. While the demand for polyester full stretch yarn continues to grow in both established and emerging markets, it is important to focus on creating value-added products that meet the specific needs of different industries. Whether it’s improving the performance characteristics of yarn or ensuring its compatibility with various textile production processes, understanding the unique requirements of customers can significantly enhance a manufacturer’s position in the market.

Geographical market dynamics also play a key role in shaping the future of polyester yarn. In regions such as Asia-Pacific, where textile manufacturing is thriving, demand for high-quality FDY yarn is especially strong. Similarly, expanding consumer markets in Africa and Latin America present new opportunities for export, driven by rising demand for affordable and durable textile products. Manufacturers that can tap into these growing markets, while also maintaining high-quality production, will have a clear advantage over their competitors.

In a rapidly evolving global market, polyester full stretch yarn manufacturers must remain adaptable to meet customer needs while staying competitive in terms of pricing and sustainability. By focusing on quality, innovation, and sustainable practices, businesses can continue to thrive in an increasingly crowded and challenging marketplace. As the demand for FDY yarn continues to rise, manufacturers and exporters who understand the market trends and challenges will be better positioned to seize the opportunities ahead.

English

English 中文简体

中文简体

Home

Home